PRODUCTS

TECHNICAL SPECIFICATIONS

- Special design dimensions according to customer demand

- Up to 1.400°C temperature

- Forklift or special design loading/unloading systems

- Up to 100 tons charge capacity

- Heating system: electricity, NG or LPG

- Self-recuperative burners or central recuperation to reduce operating costs

- Optimum insulation quality with required engineering calculations

- Low energy consumption

- Optimum temperature homogeneity

- Special design circulation systems for low temperature processes

- Special design muffle system

- Automatically or manual quenching systems (water, oil or polymer)

- Protective atmosphere systems

- Fully automatic PLC control system

- Compliant with AMS & CQI-9 requirements

PROCESSES

- Annealing

- Hardening

- Tempering

- Normalizing

- Stress Relieving

- Curing

- Pre-Heating

- Carburizing

♦ Automotive ♦ Energy ♦ Defense ♦ Aviation ♦ Iron & Steel Industry (Steel Plant, Foundry, Forging & Rolling Shop) ♦ Commercial Heat Treatment

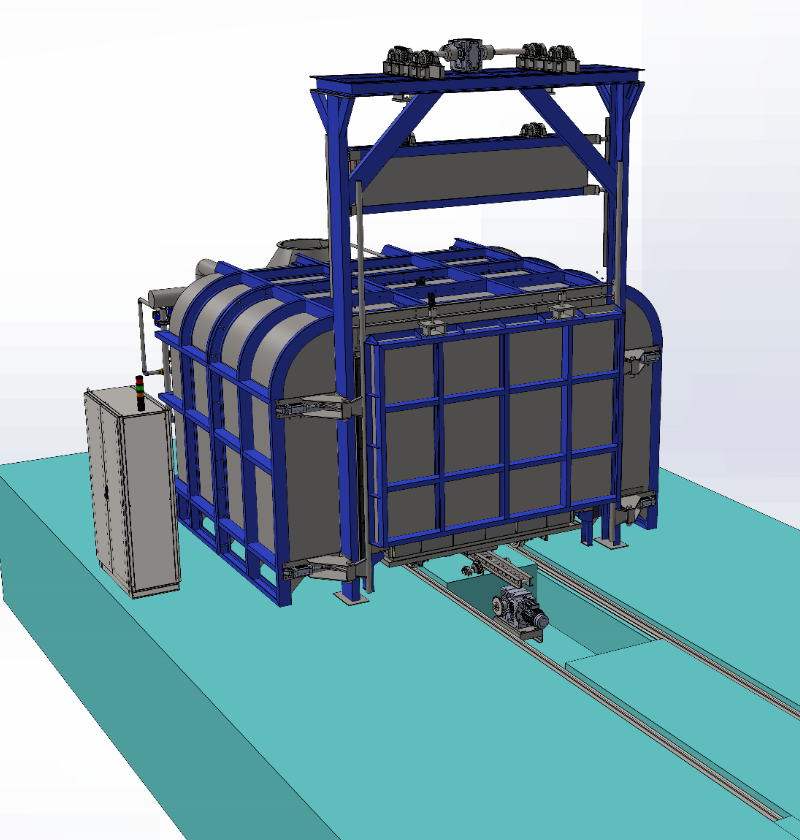

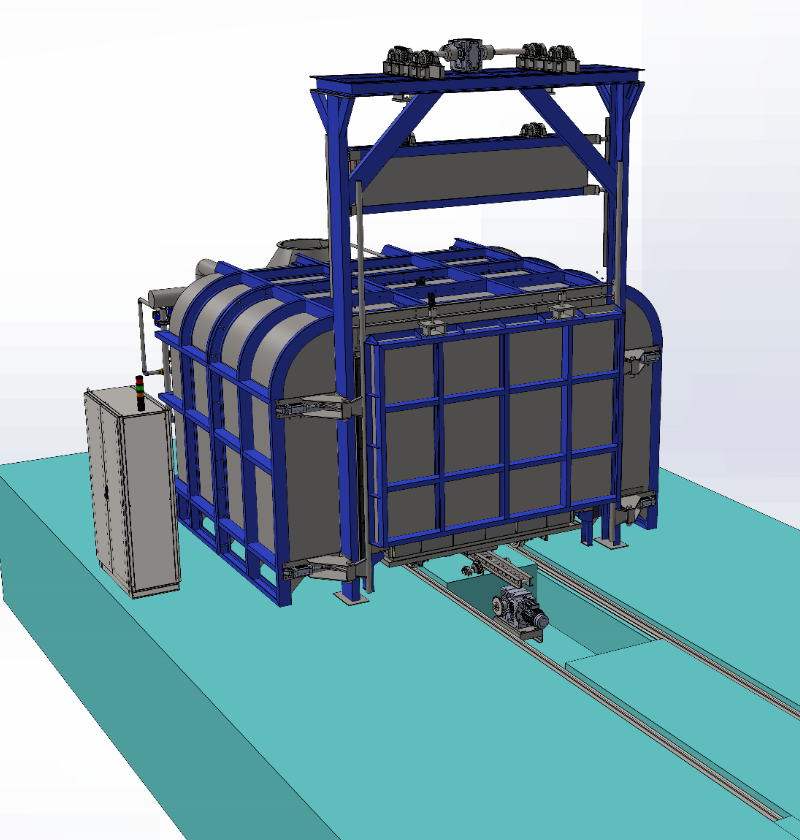

TECHNICAL SPECIFICATIONS

- Special design dimensions according to customer demand

- Up to 1.400°C temperature

- Up to 200 tons charge capacity

- Heating system: electricity, NG or LPG

- Guillotine or coupled door (Single or double door)

- Bogie hearth (single or double bogie)

- Self-recuperative burners or central recuperation to reduce operating costs

- Optimum insulation quality with required engineering calculations

- Low energy consumption

- Optimum temperature homogeneity

- Special design circulation systems for low temperature processes

- Special design muffle system

- Automatically or manual quenching systems (water, oil or polymer)

- Protective atmosphere systems

- Fully automatic PLC control system

- Compliant with AMS & CQI-9 requirements

PROSESLER

- Annealing

- Hardening

- Tempering

- Normalizing

- Stress Relieving

- Curing

- Pre Heating

♦ Automotive ♦ Energy ♦ Defense ♦ Aviation ♦ Iron & Steel Industry (Steel Plant, Foundry, Forging & Rolling Shop) ♦ Commercial Heat Treatment

TECHNICAL SPECIFICATIONS

- Special design dimensions according to customer demand

- Up to 1.200°C temperature

- Up to 10 ton/hour charge capacity

- Heating system: electrticity, NG or LPG

- Self recuperative burners or central recuperation to reduce operating costs

- High quality centrifugal casting stainless steel rollers

- Optimum insulation quality with required engineering calculations

- Low energy consumption

- Optimum temperature homogeneity

- Special design circulation systems for low temperature processes

- Special design muffle system

- Automatically quenching systems (water, oil or polymer)

- Automatic loading & unloading option

- Protective atmosphere systems

- Full automatically PLC control system

- Compliant with AMS & CQI-9 requirements

PROCESSES

- Annealing

- Isothermal Annealing

- Bright Annealing

- Hardening

- Tempering

- Normalizing

- Stress Relieving

- Re-Heating

- Spheroidising

- Quench (Water, Oil, Polymer)

♦ Automotive ♦ Energy ♦ Defense ♦ Aviation ♦ Iron & Steel Industry (Steel Plant, Foundry, Forging & Rolling Shop)

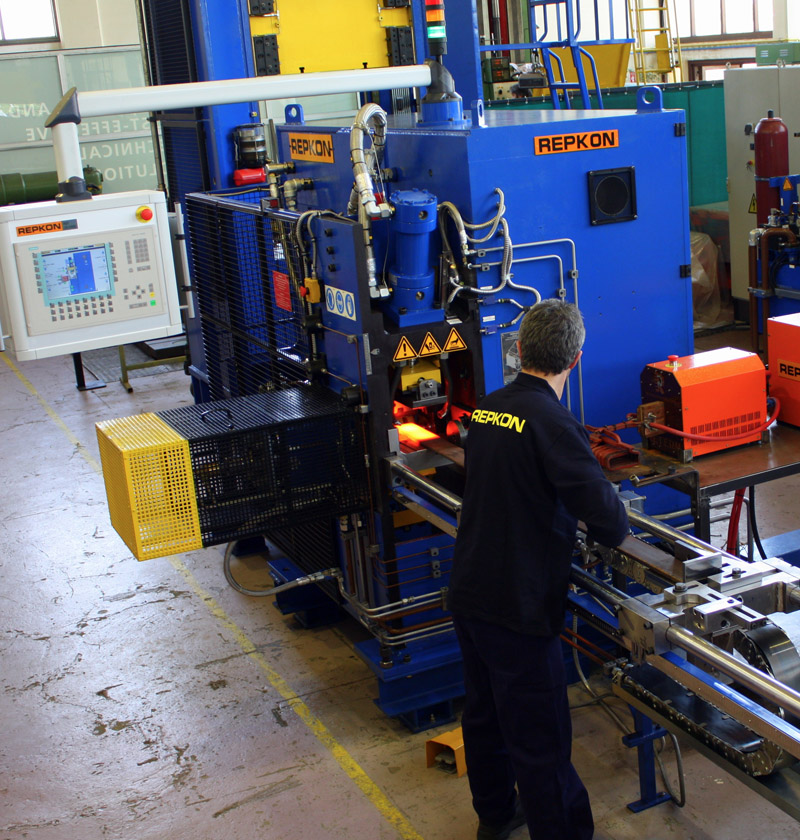

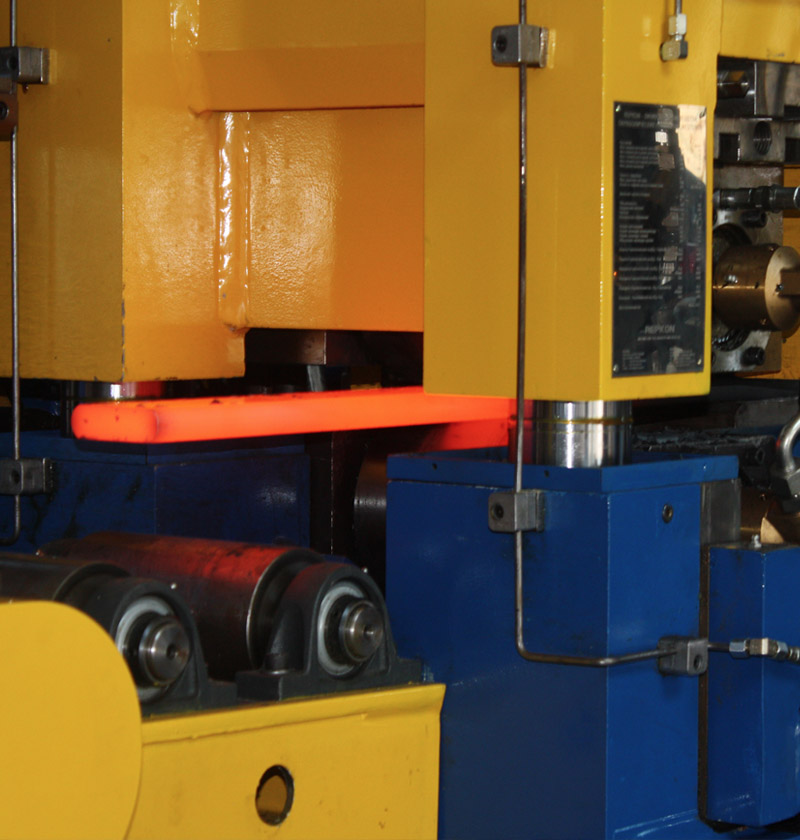

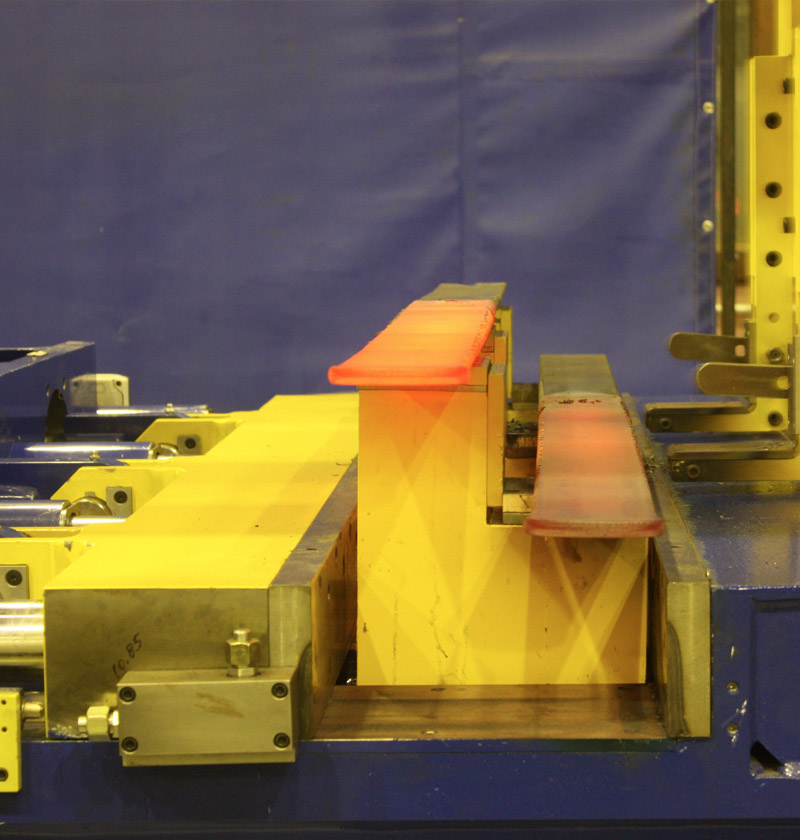

TECHNICAL SPECIFICATIONS

- Special design dimensions according to customer demand

- Up to 1.250°C temperature

- Hydraulic or mechanical drive walking beam system

- Up to 30 ton/hour charge capacity

- Heating system: electrticity, natural gas, LPG

- Self recuperative burners or central recuperation for reduce operating costs

- Optimum insulation quality with required engineering calculations

- Low energy consumption

- Oxygen level measurement system

- Optimum temperature homogeneity

- Special design muffle system

- Automatically quenching systems (spray quench)

- Automatic loading & unloading option

- Full automatically PLC control system

- Compliant with AMS & CQI-9 requirements

PROCESSES

- Annealing

- Hardening

- Normalizing

- Stress Relieving

- Curing

- Quench (Spray Quench)

♦ Automative (Leaf Spring, Coil Spring, Stabilzer Bar, etc.) ♦ Energy ♦ Industry (LPG, CNG Cylinder Production) ♦ Defense Industry ♦ Iron & Steel Industry (Pre-Heating for Rolling)

TECHNICAL SPECIFICATIONS

- Special design dimensions according to customer demand

- Up to 1.200°C temperature

- Hydraulic or mechanical drive bell system

- Up to 100 ton charge capacity

- Heating system: electrticity, natural gas, LPG

- Self recuperative burners or central recuperation for reduce operating costs

- Optimum insulation quality with required engineering calculations

- Low energy consumption

- Special design circulation system

- Optimum temperature homogeneity

- Special design muffle system

- Protective atmosphere option

- Automatic loading & unloading option

- Full automatically PLC control system

- Compliant with AMS & CQI-9 requirements

- Suitable for continuous processes

PROCESSES

- Nitriding

- Carburizing

- Annealing

- Hardening

- Normalizing

- Stress Relieving

- Tempering

- Spheroidising

- Quench (Water, Oil, Polymer, Salt and Fluidized Bed)

♦ Automative ♦ Energy Industry ♦ Farming Industry ♦ Building Industry ♦ Iron & Steel Industry (Pre-Heating for Rolling) ♦ Commercial Heat Treatment

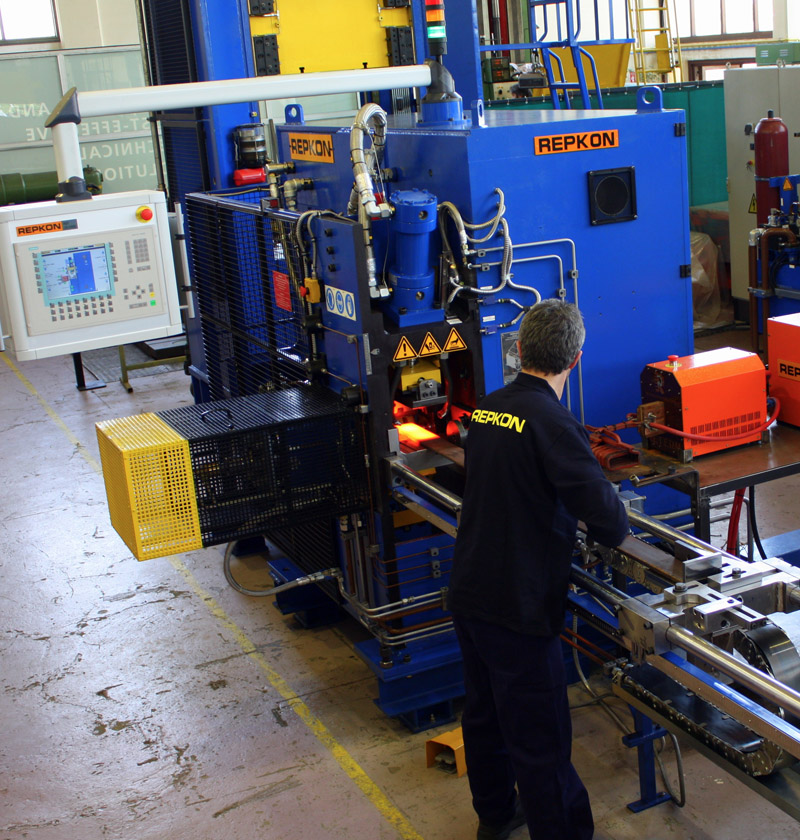

- Cambering Press

- Center Hole Punching Machine

- Eye Rolling Machine

- Tapper Rolling Machine

- Edge Cutting Machine

- Transfer Systems

- Robots

- Manipulators

- Conveyors

- Heat Treatment System

- Hardening Furnace

- Quenching Tank

- Tempering Furnace

- End Heating Furnace

- Center Hole Heating Furnace

As the Calor company we can supply for you the complete leaf spring production line. Please contact us for solutions in various capacities and suitable for your products.

- Bending Tables and bending machines

- Automatic & Semi-Automatic Spade Forging Cells

- Transfer Systems

- Robots

- Manipulators

- Conveyors

- Heat Treatment System

- Pre-Heating Furnace

- Hardening Furnace

- Quenching Tank

- Tempering Furnace

As the Calor company we can supply for you the complete stabilizer production line. Please contact us for solutions in various capacities and suitable for your products.